Commercial Food Service Equipment

Your Premier Partner in Custom Electric Motors for Commercial Food Service Equipment!

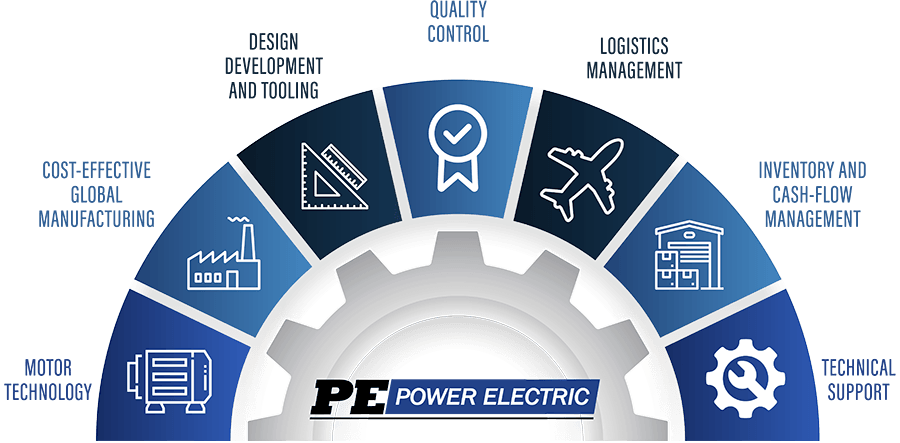

For over 30 years, OEMs have partnered with Power Electric to develop optimized electric motors and gear motors tailored to the unique specification of the commercial food service equipment industry. Our unwavering commitment to quality, innovation, and reliability positions us as the preferred choice for OEMs seeking unmatched motor solutions for their products.

Our motors are engineered and manufactured to thrive in the demanding environments of commercial kitchens. Renowned for their field reliability, our motors ensure consistent performance, minimize downtime, and contribute to the longevity of your products.

Collaborate with our skilled engineering team to develop motor solutions that seamlessly integrate into a wide range of commercial food service equipment. Whether you need compact motors to save space or high-performance options for high duty cycle applications, we have you covered.

At Power Electric, we value our partnerships. Our dedicated support team is always ready to support you throughout the entire development process - from initial consultations to quality and inventory management to post-sales support. Your success is our priority.

Applications / Machines

- Commercial grills

- Conveyor ovens

- Toaster ovens

- Food packaging equipment

- Frozen beverage machines

- Pumps

- Softserve Machines

- Ice making/dispensing machines

- Mixers/blenders

- Popcorn machines

- Slicing machines

- Hot & Cold beverage dispensers

- Coffee machine pumps/whippers

- Commercial dish washers

Key Attributes

- World Class Field Reliability

- High-Efficiency designs

- R290 approved solutions

- Compact, power-dense configurations

- Agency approvals

- Long life + high duty cycle operation

- Extreme operating temperature range

- Internal safety feature options

Motor Types

OEM Benefits

- Feature, performance, price optimization

- Development time and cost minimization

- Competitive differentiation

- Agency certifications included

- Customized solution without the risk

- Reduce internal resource consumption

- Improve cash flow

- Increase on-time delivery

- Minimize inventory

Design. Sourcing. Quality. Logistics. Support.

Request a Quote

Request a Quote