Automatic Door Operators

Trusted Electric Motor and Gear Motor Solutions for Automatic Door OEMs

Power Electric has partnered with the world’s leading automatic door operator manufacturers for more than two decades. We take pride in providing door operator OEMs with the most reliable, yet cost effective, gear motor solutions to fit their particular operator type.

Automatic door manufacturers rely on Power Electric’s expertise and experience to provide motor and gear motor engineering, design, production, quality, and logistics services. Whether you are kicking off a new R&D project or need to improve an existing product, our technical experts’ partner with you to identify and deliver the optimal solution for your specific application needs.

Types of Automatic Door Operation

Swing Door Operators

Hospitals, clinics, and retail locations will typically use an electric swing door. A rugged and durable gear motor that is quiet in operation is just as important as its longevity. Power Electric ensures the highest quality, durability and reliability and we work to continuously maintain and improve.

Slide Door Operators

Electric sliding doors found in public buildings are designed to add customer convenience. Electric sliding doors on elevators is a requirement. Both types of electric sliding doors must operate quietly and efficiently, relying on the power behind its electric gear motor inside. Typical electric sliding doors are interior doors and may not need the IP ratings of exterior door use.

Revolving Door Operators

Electric revolving doors save energy by reducing the drafts of air that escapes through swing or slide doors. These types of doors also improve traffic flow in commercial areas. Revolving doors must be powered by a gear motor that meets energy efficient standards as well as have a long lifespan. Contact us to talk through how your revolving door operators can benefit from housing a Power Electric-sourced gear motor.

Overhead Door Operators

Also commonly referred to as garage door openers, we focus on commercial-grade operators for motor and gear motor applications. Motors and gear motors for these heavy doors must operate with precise torque and efficiency, be extremely reliable and durable and able to withstand environmental demands. Learn more on IP Ratings to discover what it means and contact us to discuss what’s right for your needs.

Key Motor Attributes

- Withstand cold temperatures

- High Duty Cycle

- Quiet Operation

- Moderate torque density and efficiency

- Rugged and reliable even in extreme environments

Motor Types

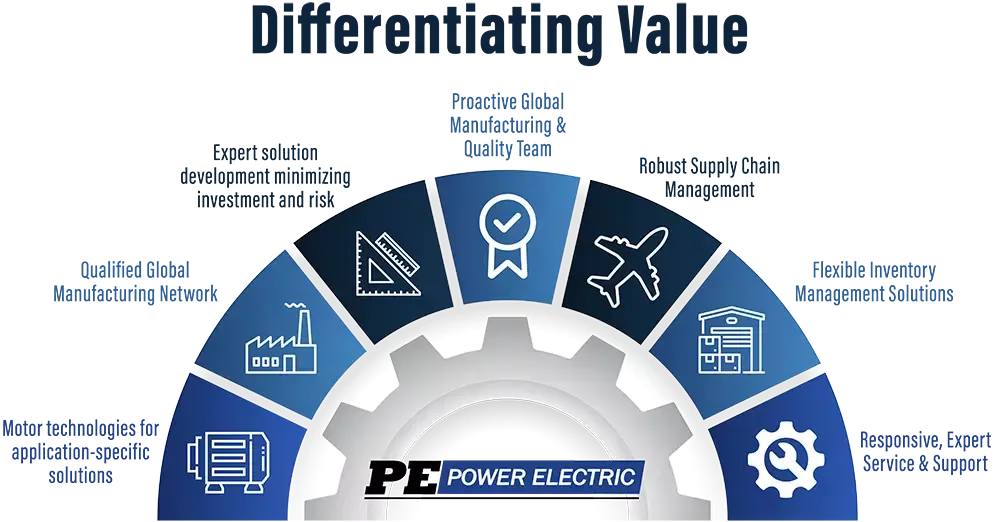

Design. Sourcing. Quality. Logistics. Support.

Request a Quote

Request a Quote