Custom Motors vs. Standard Motors

This article was featured in Design World Magazine and Designworldonline.com

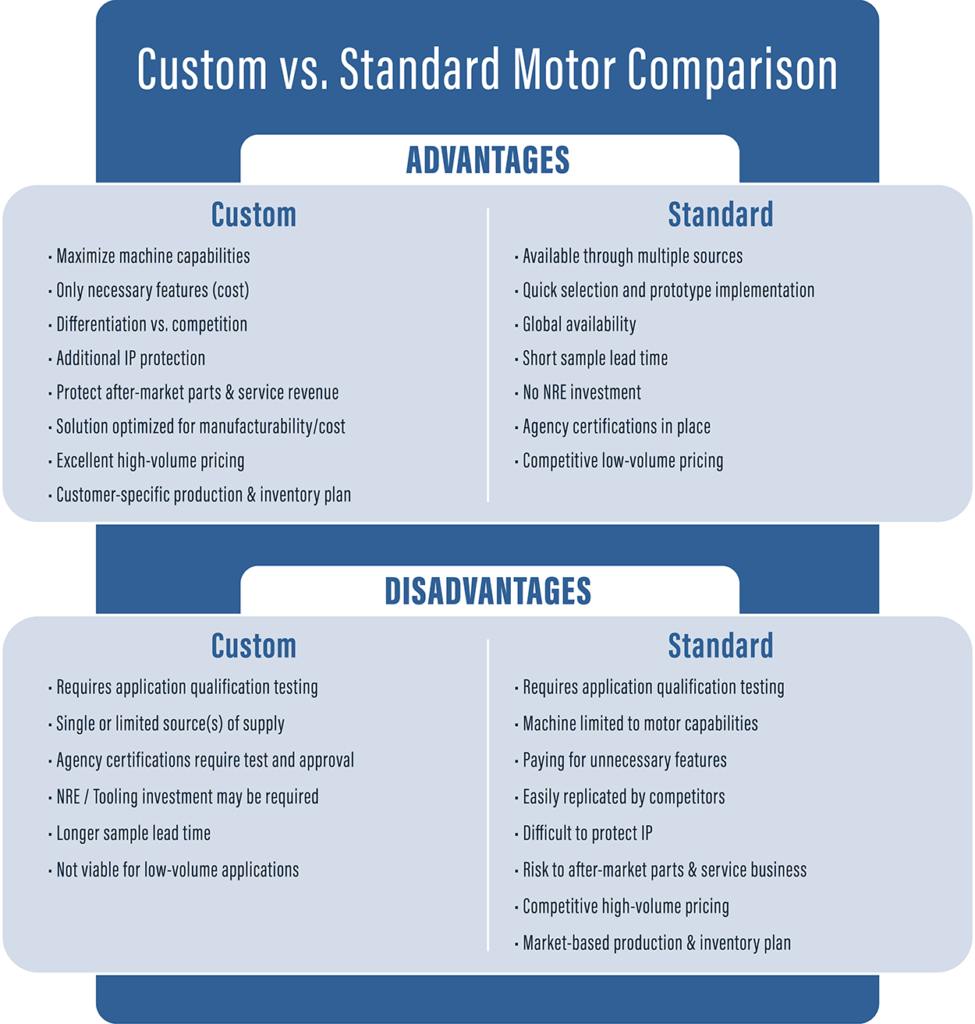

Machine builders have a lot to consider when designing solutions for a specific application. One key consideration is to determine whether it is better to design around a standard, off-the-shelf motor, or to design a custom motor that precisely matches the application requirements. Some essential aspects when comparing standard to custom-built motors include performance, availability, cost, IP protection, and aftermarket support. This article examines the pros and cons of each solution when comparing standard and custom motors.

Customized motor solutions allow the machine designer to optimize motor performance, fit, and cost to their unique application requirements. Customizations can range from simple shaft modifications to complex, complete motor redesigns. These solutions typically require a development effort to bring the design to full rate production, which requires resources and time on the front end.

Standard motors are fully designed and developed solutions meant to cover a wide range of potential applications. While price competitive and typically available with short lead times through multiple sources, standard motors are limited in their range of available options.

The following should be considered when choosing between a standard motor and a custom designed motor.

Equipment Performance

Frequently the most important consideration between custom and standard motor options is the desired performance of the machine. This can be reduced to a single question: “Would it be preferable to design the machine around the most-applicable standard motor available or to design a motor to the requirements of the machine?”

For many applications, a standard motor solution will address most, if not all, of the feature and performance requirements of the overall machine design. With the motor specifications documented, pricing established, lead time published, and authorized resellers in place, the equipment manufacturer can quickly select and source an appropriate standard motor that provides at least the required capabilities for their machine. One potential downside to the efficiency of an applied standard solution is that it often includes features that are not required by the application or is missing features or capabilities that are desired. This less optimized solution could increase costs for unnecessary features or limit the capability or marketability of the overall machine.

With a customized solution, the machine designer determines the requirements that enable the motor to reach maximum capability and to be optimized to those specific requirements with no extra or missing features. For example, motor windings can be modified to achieve exactly the desired application speed and torque, which results in a more efficient and cost-effective machine. Adjusting motor length and diameter, while maintaining critical torque requirements, allows the designer to better utilize available space without sacrificing performance capabilities. The potential trade-offs with an application-specific solution is the time and initial investment to properly develop the unique motor, which is only available from a single supplier.

Costs

Most standard motors are priced to meet general market needs. Motors sold through multiple vendors, distributed through sales channels, and purchased online can be cost effective, particularly when purchased in low quantities. However, included motor features not required by a specific application can contribute to unnecessary costs, especially in high-volume applications.

A custom motor solution typically includes an initial development cost associated with non-recurring engineering (NRE), production tooling, agency certification, and other related activities. In a ground up, total redesign, the development costs can be substantial and are rarely feasible for low-volume applications. The development process often results in lower per unit production costs that quickly offset the up-front investment once the motor is in full production. The elimination of unneeded standard motor features also reduces the per unit cost of a customized motor.

Aftermarket Availability and Support

Machine manufacturers wishing to maximize their aftermarket service or parts revenue stream will find it challenging when using standard motors since they are readily available through multiple vendors. Standard motors could be effective for this purpose if the motor vendor is willing to private label their standard motor to camouflage its identity. Readily available standard products allow the manufacturer to minimize aftermarket support efforts (and bypass revenue) by allowing their customers to order motors from a vendor of their choice.

A frequently overlooked advantage of a customized motor design is that the design often becomes a proprietary solution of the purchasing company, so that any aftermarket needs of end users must be purchased through the machine builder - not the motor manufacturer or their distribution channel. This ensures that customers contact the machine manufacturer first with service needs, which allows the manufacturer to handle parts and service sales in their preferred manner.

Intellectual Property Protection

As with consumer aftermarket support, intellectual property protection with a standard motor may be challenging as competitors can readily obtain the same motor, or a similar competitive motor, to develop a machine with comparable performance capabilities. Brand labeling of standard motors can help disguise the motor vendor to make it difficult to discover its source and capabilities. Using a standard motor to design a machine opens the door for competitors to use the same exact motor and potentially negate any market advantage.

A customized design provides additional protection against a competitor copying a machine design element or motor feature. The customized design carries a unique, unpublished part number assigned to a specific customer that makes it much more difficult for competitors to ascertain the motor or its specifications. Due to the initial development costs and time required for a new supplier to engineer, tool, and manufacture the custom motor, the investment for a competitor to create a comparable solution would be high.

Lead Time and Availability

In limited quantities, standard motors are typically available from stock or with relatively short lead times through the vendor or their distributors. Since standard motors are sold to numerous customers across many markets, production forecasts and inventory levels affected by abrupt changes in demand will impact all customers of that motor.

Custom designs with unique features initially take longer to build. Initial lead times for custom motor designs include time for engineering, documentation, tooling and preliminary material procurement prior to production build time. Custom designs provide flexibility in delivery schedules and future planning. While some components may be shared with standard products, the specific requirements of the custom motor dictate product flow to meet an individual customer’s demand needs. Customer-specific inventory plans are commonly implemented to maintain short and consistent lead times for custom motors.

Qualification Testing and Agency Approvals

The initial qualification of a new motor to be used on a particular machine is needed with either a standard or custom motor. Most high-volume customers will not approve a new motor solution until the initial sample tests on a prototype machine are conducted. Agency approvals are established for standard product lines when developed and become part of the product specification. Since custom products can deviate from the initial agency testing protocol, they will need to qualify as a new product with the appropriate testing protocol. Agency approvals of a ground up design can significantly increase time and cost investments.

Conclusion

The decision between using standard or custom motors should be carefully deliberated. It is important to look at overall revenue impact vs. the initial costs to determine which offers the best value over the machine life cycle. A custom design can provide competitive differentiation that increases sales instead of settling for a standard solution. Conversely, a standard design increases speed to market to help capture initial sales that might otherwise be missed while waiting for the development of a custom solution.

Let's talk about your project

Set up a Consultation

Next Steps -

A motor expert will contact you after reviewing your requirements.

If needed, we can sign an NDA to ensure privacy.

We create a detailed proposal with a timeline, cost estimates, prototypes, etc.

The Power Electric team will collaborate with you to make your next custom motor project successful and give you a competitive advantage! Please complete our contact form.

Request a Quote

Request a Quote