Motorized Medical Equipment

Compact and Reliable Motors and Gear Motors for Life-Changing Medical Equipment

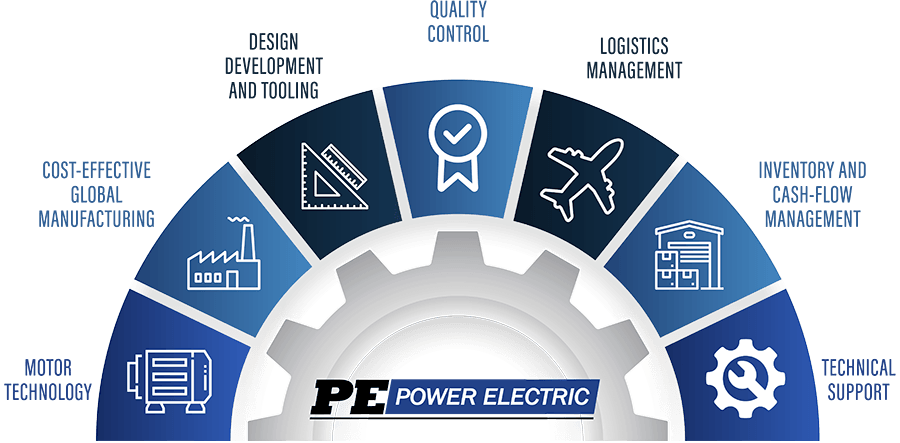

At Power Electric, we specialize in the design and development of custom electric motors and gear motors tailored specifically for OEMs in the medical equipment industry. Our commitment to quality, innovation, and reliability positions us as the preferred choice for OEMs seeking the optimal motor solutions for their medical devices.

In a field where reliability and safety are paramount, our motors are built to deliver consistent performance in demanding medical environments, contributing to the overall safety and reliability of your medical products.

Engage with our experienced engineering team to develop custom electric motors that meet or exceed the stringent requirements and regulatory standards of the medical equipment industry, while saving you time, resources, and money.

At Power Electric, we value our partnerships. Our dedicated support team is always ready to support you throughout the entire development process - from initial consultations to quality and inventory management to post-sales support. Your success is our priority.

Applications / Equipment

- Syringe Pumps

- Dosing equipment

- Pumps

- Stair lifts

- Adjustable beds and stretchers

- Medical drills

- Medical hand tools

- Automatic Door Operators

- Medical staplers

- Fixed and portable ceiling lifts

- Rehabilitation equipment

- Automobile scooter and powerchair lift

- Laboratory automation equipment

- Wheelchair elevators

- Accessible vehicle ramps

Key Attributes

- Agency certifications

- Compact, power-dense configurations

- High-efficiency designs

- World class field reliability

- Internal safety feature options

- Highly customizable features

- Long life + high duty cycle operation

- Integrated control options

Motor Types

OEM Benefits

- Feature, performance, price optimization

- Development time and cost minimization

- Competitive differentiation

- Agency certifications included

- Customized solution without the risk

- Reduce internal resource consumption

- Improve cash flow

- Increase on-time delivery

- Minimize inventory

Design. Sourcing. Quality. Logistics. Support.

Request a Quote

Request a Quote