Brushless DC Motors

Brushless DC Motors (BLDC motors) are an excellent solution for automated equipment applications where maximum motor life, efficiency, and power density are critical requirements. Since there are no carbon brushes or a copper commutator, the only wear items in the motor are the bearings, making the BLDC motor far superior to its brushed DC motor counterpart when long operating life is required.

We offer a wide range of BLDC motor solutions that are engineered and manufactured to specifically meet or exceed your unique application requirements.

Product Attributes

- 5W – 2.2kW Output Power

- 3 – 48VDC Input Voltage

- Inner and Outer-rotor options

- 0 – 6.8 Nm (60 lb-in) Rated Output Torque Range

- 480 – 26,000 RPM Output Speed

- 10 mm to 150 mm OD frame sizes

- Integrated gearing options

- IP20 to IP66

- UL, CSA, CE, RoHS available

- Fully Customizable

Benefits

- High Efficiency, Long Life vs. brushed DC

- Maintenance free

- Higher torque density

- Cost-effective

- Compact and minimal noise

- Great for high duty cycle applications

- Excellent controllability in positioning applications

- Optimized to unique application requirements

Applications

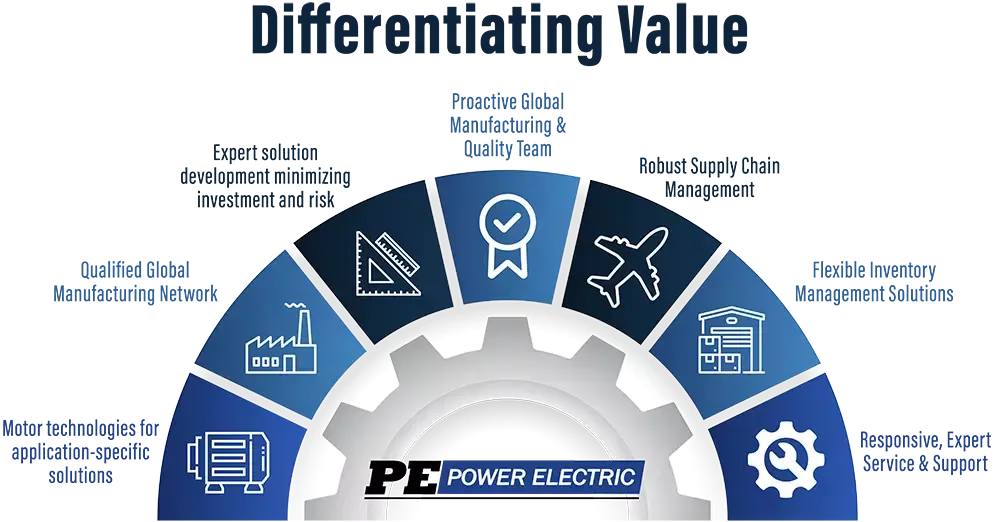

Design. Sourcing. Quality. Logistics. Support.

Request a Quote

Request a Quote