How Do AC Induction Motors Work?

If you've ever turned on a fan during a hot day or complete a load of laundry in your washing machine, you've experienced an AC induction motor firsthand. They're among the most versatile and commonly used motors in the world and one of the many types of electric motors we customize to meet your needs.

Even though induction motors are simple in design, the principles at work take a little explanation.

AC Induction Motors: A Rich History of Use

The invention of the induction motor goes back over 100 years. While several people contributed to its development, Nicola Tesla is often credited with its invention. He was the first to file for a patent in the United States in 1887.

At the same time, George Westinghouse was developing a system for electric power from alternating current, critical to the success of the induction motor. Westinghouse contracted Tesla to help develop the motor, but it wasn't until General Electric licensed and perfected the design 10 years later that the motor we use today was born.

AC Induction Motors: A Rich History of Use

The invention of the induction motor goes back over 100 years. While several people contributed to its development, Nicola Tesla is often credited with its invention. He was the first to file for a patent in the United States in 1887.

At the same time, George Westinghouse was developing a system for electric power from alternating current, critical to the success of the induction motor. Westinghouse contracted Tesla to help develop the motor, but it wasn't until General Electric licensed and perfected the design 10 years later that the motor we use today was born.

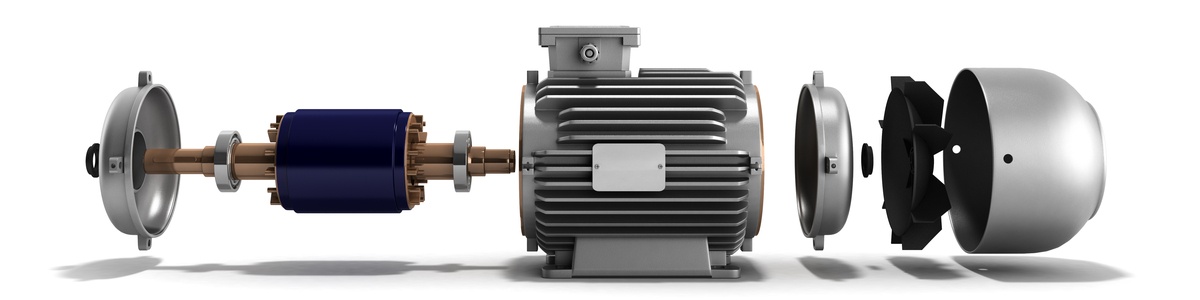

Two Basic Parts: The Stator & the Rotor

There are two main components to an AC induction motor:

- The stator

- The rotor

True to their names, the stator is an outer, non-moving, chamber in which the rotor spins. The stator creates a magnetic force through alternating current that "induces" the rotor to turn.

The Stator

The stator is formed by a ring of electromagnets. It consists of thin slotted steel or iron layers stacked together to form a cylinder. Copper wire is wound in alternating directions through the cylinder's interior creating magnetic poles.

When alternating current flows through these wire coils, they form pairs of alternating poles, one north and one south. This current causes a directional flux and the polarity of the poles to jump between north and south poles with each half cycle. This results in an alternating magnetic field that rotates with unified strength.

The Rotor

The rotor also consists of a group of electromagnets arranged around a cylinder. This axle-like apparatus nestles inside of the stator. The magnet fields induced within the rotor are attracted to the magnetic field being produced by the stator, following it as it rotates with each half-cycle of alternating current.

This type of motor is called an induction motor because the magnetic field created in the stator induces a magnetic field in the rotor. There are no permanent magnets in the rotor of an induction motor.

AC Induction Motors: A Workhorse for Any Job

AC induction motors have been around for over one hundred years and are critical components to a wide range of industrial and commercial equipment:

AC Induction Motors offer flexible, rugged, and cost effective solutions to consider for even the most demanding OEM applications.

Request a Quote

Request a Quote