Choosing the Right Process for Critical Component Approval

As a new product development or product sustainability team, ensuring that new components meet and will continue to meet specifications and quality standards is crucial to the success of any new part or product release. The two most common processes for this purpose are First Article Inspection and Production Part Approval Process. Understanding their differences and similarities will help you determine which process is right for your organization to use for approving new components or suppliers.

First Article Inspection

FAI involves a detailed verification of the first produced part against design specifications. This process typically includes:

- Preparation: Gathering all necessary documentation, such as drawings, specifications, and quality requirements.

- Inspection: Measuring and inspecting the first part using precise instruments to verify dimensions, materials, and functionality.

- Documentation: Recording all measurements and inspection results in an FAI report for review and approval.

Key Points of FAI:

- Scope: Focuses on the first produced part to ensure it meets design specifications.

- Use Cases: Ideal for initial production runs, new suppliers, or design/manufacturing changes.

- Outcome: A detailed inspection report of the first article part compared to the design specifications.

Production Part Approval Process

PPAP is a comprehensive process used predominantly in the automotive industry to ensure consistent quality in a mass production environment. Core elements include:

- Design Records: Complete drawings and specifications for the part.

- Engineering Change Documentation: Records of any design changes.

- Process Flow Diagram: Visual representation of the production process.

- Process Failure Mode and Effects Analysis (PFMEA): Identification and mitigation of potential failure modes.

- Control Plan: Detailed plan for monitoring and controlling production.

- Measurement System Analysis (MSA): Validation of measurement systems.

- Dimensional Results: Measurements of sample parts to verify specifications.

- Material and Performance Test Results: Evidence that the part meets all requirements.

- Initial Process Studies: Statistical analysis to ensure process capability and stability.

- Qualified Laboratory Documentation: Certification of testing laboratories.

- Appearance Approval Report (AAR): Approval of the part’s appearance, if applicable.

- Sample Product: Submission of sample parts for review.

- Master Sample: A reference part retained for comparison.

- Checking Aids: Tools and fixtures used for checking the part.

- Customer-Specific Requirements: Additional requirements specified by the customer.

- Part Submission Warrant (PSW): Summary document certifying PPAP completion and approval.

Key Points of PPAP:

- Scope: Covers all aspects of the production process to ensure consistent quality in mass production.

- Use Cases: Often required for high-volume production, particularly in the automotive industry.

- Outcome: Extensive documentation covering design, process, and quality control.

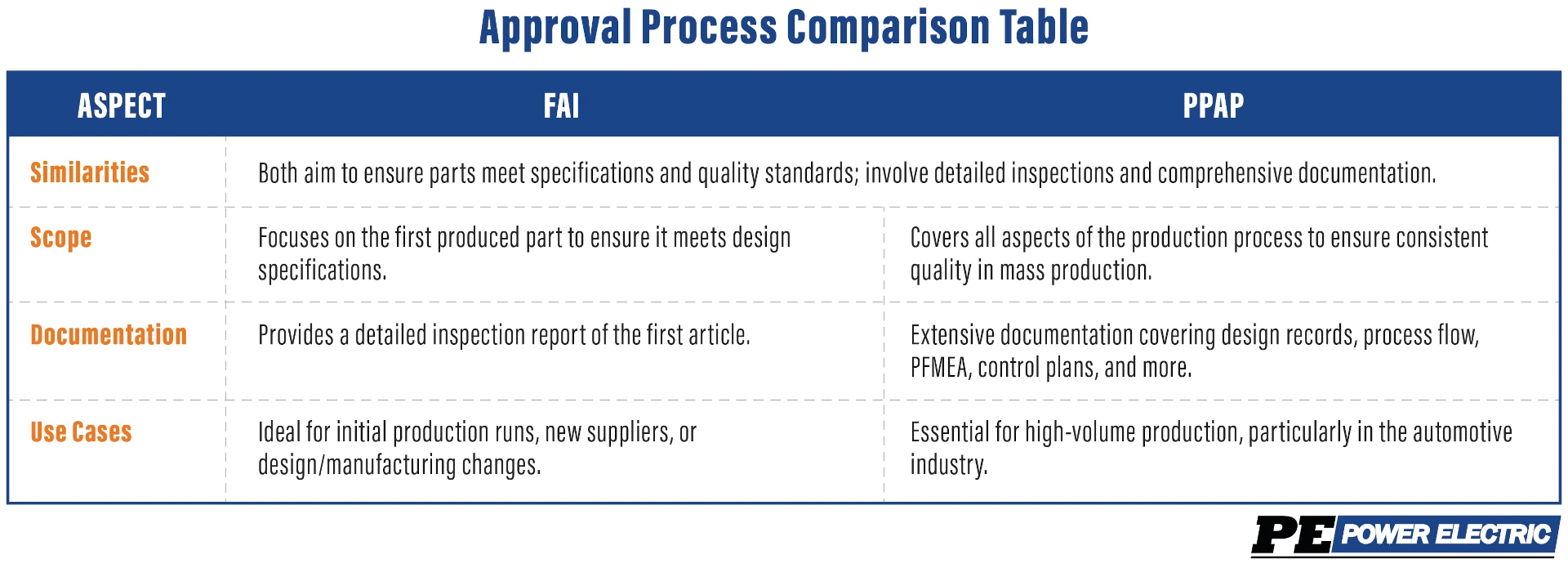

Similarities and Differences

Both FAI and PPAP aim to ensure parts meet specifications and quality standards, involving detailed inspections and comprehensive documentation. However, FAI focuses on the manufacturing process output - the first produced part, making it ideal for initial runs or design changes, while PPAP assesses the entire production process, ensuring manufacturing consistency over time in high-volume production.

Here's a summary table highlighting the similarities and differences between First Article Inspection and Production Part Approval Process:

Choosing the Right Process

The choice between FAI and PPAP depends on the product and production requirements:

- Choose FAI for detailed inspection of the first produced part, suitable for low-volume production, new product introductions, or design changes.

- Choose PPAP for a comprehensive assessment of the production process, necessary for high-volume production where consistent quality is critical.

Understanding these processes will help you make informed decisions about the approval process that is right for your business while ensuring the success of your new component or product.

Request a Quote

Request a Quote