AC Motors vs DC Motors

Electric motors drive industrial machinery and an array of devices throughout the world. The two main sources of power, alternating current (AC) and direct current (DC), are complemented by two types of electric motors that differ in operation and application. Engineers, technicians, and operators must understand the key differences between AC and DC motors to achieve optimum performance of an electrical machine or device.

The DC Motor

DC or Direct Current motors operate on power where the current flows in one direction such as the power generated from batteries or AC power sources that are rectified to direct current. The two major categories of DC motors are brushed and brushless, for more information on specifics of brushed and brushless motors, visit here: What is the difference between a brushed and brushless motor

Both types of DC motors can be matched with integral gearboxes and other accessories (such as fans) for air cooling and with additional feedback devices to improve precision. DC motors are used in a wide range of applications that include electric wheelchairs, handheld sprayers and pumps, coffee machines, off-road equipment amongst others.

Brushed DC Micro Motor

Brushed DC Motor

The AC Motor

AC motors are powered by single or three phase alternating currents. The electromagnetic field in the stator reacts with the rotor and causes the motor to rotate at a synchronous speed to match the frequency of the AC current. AC motors are efficient, durable, quiet, and flexible, which makes them a viable solution for many power generation needs.

AC motors are used in a number of applications that include food service, pumps, water heaters, lawn and garden equipment, and others.

AC Synchronous Motor

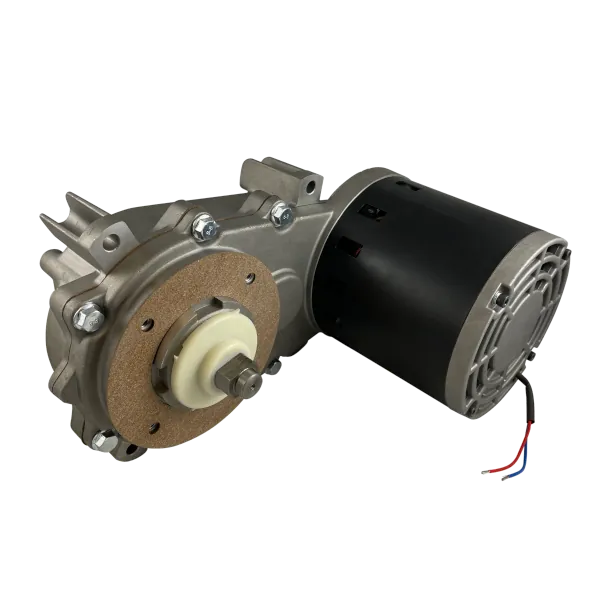

Offset AC gear motor

AC vs DC Motor Comparisons

Speed Control:

Speed can be controlled in both types of motor. AC motor velocity is controlled by the frequency of the power source. AC motors run directly off the power source and in most countries would be designed to produce a rated speed based on an input frequency of 60 Hz. However, to vary the frequency to the motor, many applications utilize specialized electronics (Variable Frequency Drives) to provide adjustable speed control. DC motor speeds can be simply controlled by varying the available DC voltage to the motor. Many control solutions exist to provide precision speed control for applications such as robotics.

Efficiency:

Three phase induction motors tend to offer improved efficiencies at higher power levels and rated speeds. Brushless DC motors offer better efficiencies across a broader range of performance and provide better performance at lower speeds and lighter loads. Brushed DC motors, however, have added components (brushes and commutator) that introduce some inefficiencies.

Maintenance:

AC motors and Brushless DC motors are preferred in most manufacturing settings since these motors require less maintenance and have longer life spans in comparison to brush DC motors, which need to be serviced more often to replace brushes or to refurbish commutator surfaces.

Cost:

AC motors are often the most cost-effective solution for large power applications and applications with constant speed and load requirements. Higher precision and increased load variations introduce more sophisticated control requirements. While brushless DC motors with higher efficiencies and additional control complexities may have higher initial costs, their lifetime costs are comparable to AC motors.

Starting Torque:

Induction motors have minimal starting torque compared with DC Motors that can be overcome with starting devices. DC motors offer higher starting torques that translate to quick accelerations. Many applications that require fast indexing and quick move and settle times require high acceleration capabilities.

Applications:

AC motors make up a large volume of electric motors sold worldwide and are used in many applications such as household appliances, pumps, fans, HVAC systems, and other industrial machinery. DC motors are popular for mobile applications in electric vehicles, automated guided vehicles, and submersible ROV’s. They are also found in robotics, conveyor systems, packaging machinery, and many types of precision equipment.

In recent years, advancements in motor technology have led to more efficient and versatile options for both AC and DC motors that sometimes blur the lines between their traditional differences. Continued development in smaller and more economical electronics improves the ability to control most motors more precisely. While the original DC and AC motors were developed in the 19th century, advances in both magnet technologies and other material and fabrication processes have pushed both motor types to new performance capabilities.

Request a Quote

Request a Quote